the Highest Quality Products

Coil-Spring Suspension Components

NASCO’s production capabilities range from the simplest spring designs, such as cylindrical springs with a cylindrical bar diameter, to the more complex spring designs indicative of, say, a conical pigtail configuration with a conical bar diameter.

Likewise, NASCO is also adept at working with a wide range of intrinsic material strengths that yield low- or extremely high-stress spring characteristics, and can incorporate or develop engineering techniques to optimize these strengths.

During production, every spring is 100 percent tested as just one aspect of NASCO’s continuous quality improvement process.

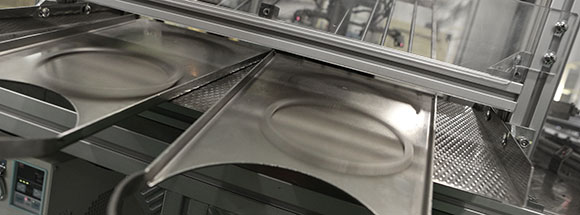

Automatic and Continuous-Variable Transmission Disc Springs

Working with both customer engineers and NHK International engineers stationed in Detroit, NASCO supplies disc springs to a multitude of leading OEMs and Tier I suppliers in the automotive industry.

By deploying industry-leading, proprietary forming, heat-treating and inspection processes, NASCO is uniquely capable of actualizing customer performance requirements, while minimizing production costs.

Trunk-Lid Torsion Bars

NASCO has become a leading provider of these obscure components that are essential to making trunk operation easy and convenient for consumers.

Six computer-controlled benders make multiple types of complex shapes with very minimal setup times. They’re likewise capable of making quick design modifications to meet ever-changing customer requirements.