Streamlined, Cost-Efficient Production

NASCO’s achievements in lightweight spring innovation are attributed to engineering advancements in manufacturing as much as design—where, unlike other suppliers, NASCO can accommodate the widest range of material and dimensional specifications, while continually developing new ways to meet the most ambitious performance requirements.

Industry-Leading Manufacturing Versatility

NASCO is equipped to be your single-source provider for coil-suspension springs, transmission disc springs and other components that fit virtually any size vehicle on the road, while meeting design aspirations to maximize spring life and even improve vehicle handling.

NASCO:

- Compared to any other supplier, can manufacture to the widest range of sizes, geometries and wire diameters

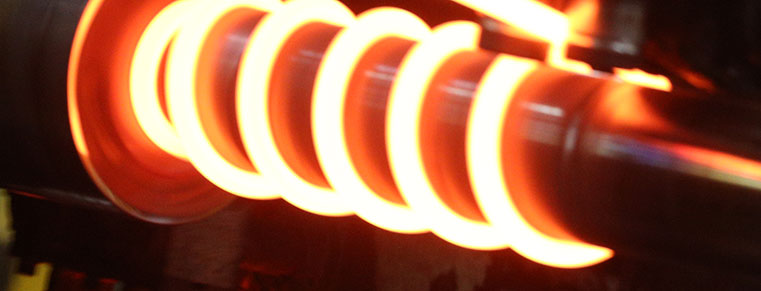

- The only supplier to offer hot and cold winding—to produce springs for all makes of cars, as well as trucks and SUVs

- Can execute clockwise or counter-clockwise winding, known to offset drift or steering pull

- Double-coating capabilities to enhance spring performance life

a Lean-Machine Method to Achieving the Highest Quality

Bringing innovative production techniques online within a Monozukuri lean-manufacturing model, NASCO is always finding ways to squeeze more cost out of the process of meeting customer QC and JIT-delivery requirements.

- In-plant prototyping line expedites turnaround for development.

- Proprietary shot-peening process makes meeting higher-stress specifications more cost effective.

- Multiple fully automated, self-contained, independent production lines—all in-house and each capable of turning raw material into a finished spring, without in-process material-handling or WIP (work-in-progress) delays. Includes:

- In-house bar processing, with wire pulling capabilities, which keeps the raw material intact, versus wire turning that leaves some of your material cost, literally, on the floor in the form of scrap

- 100% quality check for material imperfections down the line

- Each coil spring line has its own coating line (with single or double coat capabilities) to control paint-coating quality with minimal material handling